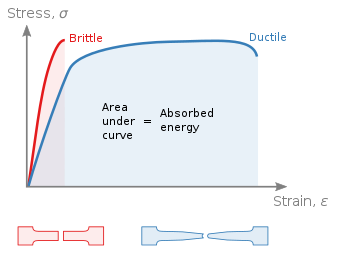

Stress–strain curve

|

Read other articles:

Daniel Gygax Informasi pribadiNama lengkap Daniel GygaxTanggal lahir 28 Agustus 1981 (umur 42)Tempat lahir Zürich, SwitzerlandTinggi 1,79 m (5 ft 10+1⁄2 in)Posisi bermain WingerSecond strikerInformasi klubKlub saat ini FC LuzernNomor 11Karier junior FC BadenKarier senior*Tahun Tim Tampil (Gol)1998–2001 FC Zürich 5 (0)2001 FC Winterthur 14 (1)2001–2002 FC Aarau 21 (3)2002–2005 FC Zürich 93 (16)2005–2006 Lille 24 (4)2007–2008 Metz 34 (5)2008–2010 1. FC Nure…

本條目存在以下問題,請協助改善本條目或在討論頁針對議題發表看法。 此條目需要补充更多来源。 (2018年3月17日)请协助補充多方面可靠来源以改善这篇条目,无法查证的内容可能會因為异议提出而被移除。致使用者:请搜索一下条目的标题(来源搜索:羅生門 (電影) — 网页、新闻、书籍、学术、图像),以检查网络上是否存在该主题的更多可靠来源(判定指引)。 此�…

Allium amplectens Klasifikasi ilmiah Kerajaan: Plantae Divisi: Tracheophyta Kelas: Liliopsida Ordo: Asparagales Famili: Amaryllidaceae Genus: Allium Spesies: Allium amplectens Nama binomial Allium amplectensTorr. Allium amplectens adalah spesies tumbuhan yang tergolong ke dalam famili Amaryllidaceae. Spesies ini juga merupakan bagian dari ordo Asparagales. Spesies Allium amplectens sendiri merupakan bagian dari genus bawang Allium.[1] Nama ilmiah dari spesies ini pertama kali diterbitkan…

مجد عزت الشربجي معلومات شخصية الميلاد 1981 (العمر 43 سنة)داريا مواطنة سوريا الحياة العملية المدرسة الأم جامعة دمشق المهنة ناشِطة اللغات العربية الجوائز جائزة نساء الشجاعة الدولية (2015) تعديل مصدري - تعديل مجد عزت الشربجي (ولدت: 1981) هي ناشطة سلام سورية. في عا…

Мечеть Милинди в городе Занзибар Ислам на Занзибаре является религией большинства в автономной провинции Танзании Занзибар. Согласно данным ЦРУ и МИД России 99 % жителей Занзибара исповедует ислам[1][2]. Мечеть Каменного города Содержание 1 История 2 Современное п…

Об экономическом термине см. Первородный грех (экономика). ХристианствоБиблия Ветхий Завет Новый Завет Евангелие Десять заповедей Нагорная проповедь Апокрифы Бог, Троица Бог Отец Иисус Христос Святой Дух История христианства Апостолы Хронология христианства Ранне…

1833 Vermont gubernatorial election ← 1832 September 3, 1833 (1833-09-03) 1834 → Nominee William A. Palmer Ezra Meech Party Anti-Masonic Democratic Popular vote 20,565 15,683 Percentage 52.9% 40.3% Governor before election William A. Palmer Anti-Masonic Elected Governor William A. Palmer Anti-Masonic Elections in Vermont Federal government Presidential elections 1792 1796 1800 1804 1808 1812 1816 1820 1824 1828 1832 1836 1840 1844 1848 1852 1856 1…

1937 film by W. S. Van Dyke Rosalie1937 lobby cardDirected byW. S. Van DykeWritten byWilliam Anthony McGuireBased onRosalie1928 playby Guy BoltonProduced byWilliam Anthony McGuireStarringEleanor PowellNelson EddyFrank MorganCinematographyOliver T. MarshEdited byBlanche SewellMusic byCole PorterProductioncompanyMetro-Goldwyn-MayerDistributed byLoew's Inc.Release date December 24, 1937 (1937-12-24) Running time122 minutesCountryUnited StatesLanguageEnglish Rosalie is a 1937 American…

Forested headland nature reserve Balls Head ReserveSydney red gum at Balls Head ReserveLocation in Greater metropolitan SydneyTypeNature reserveLocationBalls Head Drive, Waverton, North Sydney Council, New South Wales, AustraliaNearest citySydneyCoordinates33°50.8′S 151°11.7′E / 33.8467°S 151.1950°E / -33.8467; 151.1950Designated1926 by Premier Jack LangEtymologyHenry Lidgbird BallManaged byNorth Sydney Council Waterhole at Balls Head, probably created o…

Association football club in England This article relies largely or entirely on a single source. Relevant discussion may be found on the talk page. Please help improve this article by introducing citations to additional sources.Find sources: Burscough F.C. – news · newspapers · books · scholar · JSTOR (August 2018) Football clubBurscoughFull nameBurscough Football ClubNickname(s)Green Army, LinnetsFounded1946; 78 years ago (1946)GroundTh…

Questa voce sugli argomenti allenatori di calcio svizzeri e calciatori svizzeri è solo un abbozzo. Contribuisci a migliorarla secondo le convenzioni di Wikipedia. Segui i suggerimenti dei progetti di riferimento 1, 2. Fernand Jaccard Nazionalità Svizzera Altezza 176 cm Calcio Ruolo Allenatore (ex Centrocampista) Carriera Squadre di club1 1924-1927 La Chaux-de-Fonds? (?)1934-1936 Montreux-Sports? (?)1936-1940 Basilea? (?) Nazionale 1934-1936 Svizzera12 (0) Carriera da …

Leader of the Nizari Ismaili state from 1162 to 1193 This article includes a list of general references, but it lacks sufficient corresponding inline citations. Please help to improve this article by introducing more precise citations. (September 2011) (Learn how and when to remove this message) DāʿīRashid ad-Din Sinanراشد الدين سنانEngraving of Rashid ad-Din Sinan.Lord of the Nizari Ismaili state in SyriaIn office1162–1193 PersonalBornAbu al-Hasan Sinan ibn Sulayman ibn…

2013 UCI Road World ChampionshipsVenueTuscany, ItalyDate(s)22–29 September 2013Nations participating76Events12← 20122014 → Events at the 2013 UCIRoad World ChampionshipsParticipating nationsQualificationElite eventsElite road racemenwomenElite time trialmenwomenElite team time trialmenwomenUnder-23 eventsUnder-23 road racemenUnder-23 time trialmenJunior eventsJunior road racemenwomenJunior time trialmenwomenvte The 2013 UCI Road World Championships took place in Tuscany, …

José Salvatierra Nazionalità Costa Rica Altezza 178 cm Peso 78 kg Calcio Ruolo Difensore Squadra Sporting San José CarrieraSquadre di club1 2009-2021 Alajuelense221 (8)2022 Sporting San José5 (0)Nazionale 2011-2017 Costa Rica36 (0)Palmarès Gold Cup Bronzo USA 2017 1 I due numeri indicano le presenze e le reti segnate, per le sole partite di campionato.Il simbolo → indica un trasferimento in prestito. Statistiche aggiornate al 12 agosto 2022 Modifica dati su…

この項目には、一部のコンピュータや閲覧ソフトで表示できない文字が含まれています(詳細)。 数字の大字(だいじ)は、漢数字の一種。通常用いる単純な字形の漢数字(小字)の代わりに同じ音の別の漢字を用いるものである。 概要 壱万円日本銀行券(「壱」が大字) 弐千円日本銀行券(「弐」が大字) 漢数字には「一」「二」「三」と続く小字と、「壱」「弐」…

西維珍尼亞 美國联邦州State of West Virginia 州旗州徽綽號:豪华之州地图中高亮部分为西維珍尼亞坐标:37°10'N-40°40'N, 77°40'W-82°40'W国家 美國加入聯邦1863年6月20日(第35个加入联邦)首府(最大城市)查爾斯頓政府 • 州长(英语:List of Governors of {{{Name}}}]]) • 副州长(英语:List of lieutenant governors of {{{Name}}}]])吉姆·賈斯蒂斯(R)米奇·卡邁克爾(英�…

Military forces of Cuba Revolutionary Armed ForcesFuerzas Armadas Revolucionarias (Spanish)Emblem of the Cuban Revolutionary Armed ForcesFounded1868; 156 years ago (1868)Current form1960; 64 years ago (1960)Service branchesRevolutionary ArmyRevolutionary Air and Air Defence ForceRevolutionary NavyTerritorial Troops MilitiaYouth Labor ArmyDefence and Production BrigadesHeadquartersHavana, CubaLeadershipFirst SecretaryMiguel Díaz-CanelCommander-in-chief Pr…

2016年美國總統選舉 ← 2012 2016年11月8日 2020 → 538個選舉人團席位獲勝需270票民意調查投票率55.7%[1][2] ▲ 0.8 % 获提名人 唐納·川普 希拉莉·克林頓 政党 共和黨 民主党 家鄉州 紐約州 紐約州 竞选搭档 迈克·彭斯 蒂姆·凱恩 选举人票 304[3][4][註 1] 227[5] 胜出州/省 30 + 緬-2 20 + DC 民選得票 62,984,828[6] 65,853,514[6] 得…

Supreme Court of the Republic of TexasSeal of the Republic of TexasEstablished1836LocationAustin, TexasComposition methodCongressional electionAuthorized byConstitution of the Republic of TexasNumber of positionsChief Justice, 7 District Judges (ex officio members) Part of a series on the History of Texas Timeline Pre-Columbian Texas Early Spanish explorations 1519–1543 French Texas 1684–1689 Spanish Texas 1690–1821 Mexican Texas 1821–1836 Republic of Texas 1836–184…

خريطة البعثات الدبلوماسية في باكستان هذه قائمة بالبعثات الدبلوماسية في باكستان. يوجد حاليا 79 بعثة دبلوماسية موجودة في الجيب الدبلوماسي في إسلام آباد، والعديد من الدول لها قنصليات في مدن باكستانية أخرى. يوجد في العديد من الدول سفارات غير مقيمة معتمدة من عواصم أجنبية أخرى، م�…